Electric vehicles (EVs) rely on lithium-ion batteries (LIBs) as their primary energy source, and the EV industry is experiencing unprecedented growth globally. However, the manufacturing of LIBs is associated with unique challenges that pose a hazard to workers and the environment. To protect workers, health, safety, and environment (HSE) managers of manufacturers of LIBs must introduce new safety protocols, specialized training, and Personal Protective Equipment (PPE). Therefore, there is a need to use protective garments suitable for cleanrooms such as DuPont™ Tyvek® IsoClean® to protect workers and prevent contamination in the manufacturing process.

Hazards and Personal Protective Equipment:

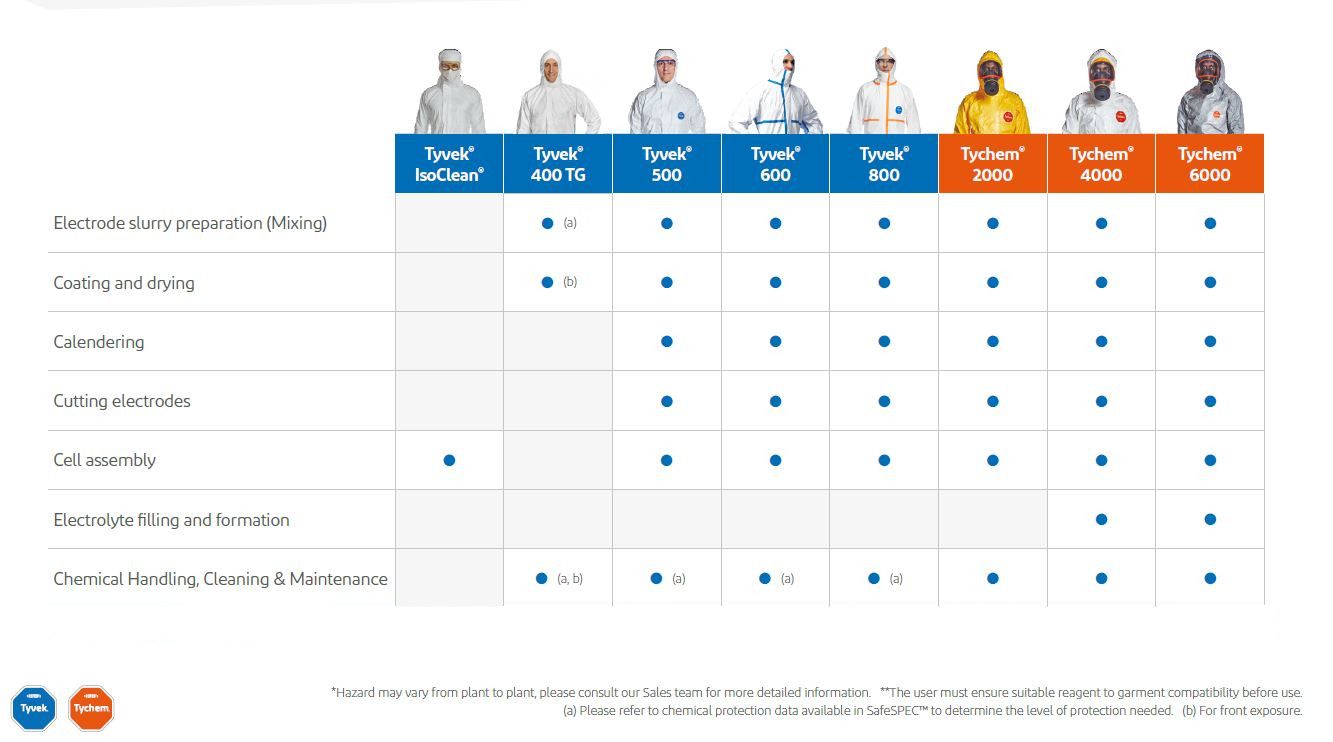

Lithium-ion batteries pose a diverse range of hazards to workers, ranging from exposure to chemicals in slurry preparation to electrolyte filling and formation. The European Chemicals Agency (ECHA) warns of severe or fatal hazards associated with certain chemicals used in manufacturing LIBs. Therefore, HSE managers must select the right PPE for the workers, such as protective garments suitable for use in cleanrooms like DuPont™ Tyvek® IsoClean®. DuPont offers a wide range of disposable chemical protective clothing and single-use cleanroom apparel solutions to protect people who encounter hazardous materials in battery cell or battery materials production.

Industries

Mining<br><br>

Refinery<br><br>

Battery Manufacturing

EV Auto Manufacturing

Battery Recycling<br><br>

Solutions:

DuPont offers Personal Protection solutions for manufacturers of batteries. The company provides suggestions on the PPE required by various value chains, from Cathode and Electrolyte Manufacturing to Cell Assembly. Additionally, DuPont Personal Protection solutions have been successfully used by leading battery manufacturers in Europe for some time. If you are interested in obtaining further suggestions on garments that can meet your need, contact DuPont.

Conclusion:

Lithium-ion battery manufacturing presents a unique set of challenges for HSE managers to protect workers and prevent contamination in the manufacturing process. To safeguard workers, HSE managers must proactively address emerging complexities. DuPont offers PPE solutions and suggestions on the equipment required at different stages of the manufacturing process to alleviate some of the hazards of LIBs and manufacturing.

DuPont Personal Protection solutions have been successfully used by leading battery manufacturers in Europe for some time. If you are interested in obtaining further suggestions on garments that can meet your need, contact us at DuPont.

Our powerful web-based tool can assist you with finding the appropriate DuPont garment for chemical or cleanroom environment -> safespec.dupont.co.uk