Tyvek® Trifecta™ A2 Fire-Rated Breather Membrane

High occupancy | Multi-occupancy | Exterior Wall

Fire risk averse A2 Euroclass non-combustible W1 grade weatherproofing breather membrane with low vapour resistance

DuPont™ Tyvek® Trifecta™ is a robust, fire-retardant breather membrane suited for external walls cladding of high-rise and higher-risk commercial and residential buildings with 3-in-1 underlaying properties:

Fire Protection = A2 (s1,d0)

Water Protection = W1 Water Resistance

Vapour Permeability = 0.416 MNsg / SD 0.08m

Need support with your next project?

Whether you're an architect, designer, engineer, builder or contractor, our technical experts offer free, tailored support and will come back to any enquiry within 48 hours.

Let’s talk and we can help deploy your next project.

Key Features and Benefits

Euroclass A2 (s1, d0) Standards: Enhances fire safety and supports fire risk-averse designs throughout the building's lifespan.

W1 Class Water-Holdout: Ensures weatherproofing performance against water, wind, rain, and dust.

U-value Preservation: Optimizes thermal efficiency when installed in the building envelope

Superior Breathability (0.416 MNsg / SD 0.08m): Provides excellent water vapor permeability for better indoor air quality

All-in-One Weatherproofing Solution: Exceeds rigorous fire risk and weatherproofing requirements, offering reliable protection

Lightweight Product: Reduces logistical complexity, saving costs and lowering carbon footprint during transportation

Wider Roll Dimension (1500 mm): Increases productivity by covering more area quickly, reducing labor time and ancillary use

6 Months Free Exposure & UV Resistance: Offers flexibility in project scheduling, minimizing UV exposure risks

25-Year Warranty: Provides long-term assurance on performance properties, ensuring durability and peace of mind for users

DuPont™ Tyvek® Trifecta™

Tyvek® Trifecta™ doesn’t produce droplets or emit smoke when subjected to flame, making it a great choice for fire risk averse build-up designs of external walls cladding. It is engineered for fast and easy installation with non-combustible A2 tape.

Airtight and watertight yet vapour-open, the Tyvek® Trifecta™ non-combustible breather membrane also contributes to energy conservation and climate control, improving the comfort of occupants and contributing to higher internal air quality.

A Comprehensive A2-s1,d0 Fire Performance System

DuPont offers a complete A2 fire performance system, for non-combustible weatherproofing and condensation risk management, for all building types. Backed by 25-year DuPont Warranty: improved fire safety throughout the building’s lifespan.

Tyvek® Trifecta™ A2 Fire-Rated Breather Membrane for external walls cladding

Robust, non-combustible breather membrane suited for high-rise and higher-risk commercial and residential buildings with 3-in-1 underlaying properties of A2 (s1,d0), W1 and 0.416 MNsg / SD 0.08m

AirGuard® A2 FR Airtight Vapour Control Layer for interior walls cladding

Non-combustible membrane for use within internal lining of roof, ceiling and wall systems. It improves airtightness, energy efficiency, and moisture management, enhancing indoor air quality and providing fire safety to the building and occupants

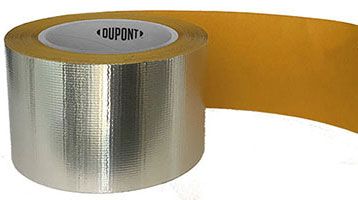

AirGuard® FR System Tape for sealing all laps and around penetrations

Fire retardant, single-sided tape A2 Fire Class to EN 13501-1. Specially formulated for use with DuPont™ AirGuard® A2 FR AVCL and DuPont™ Tyvek® Trifecta™

Need support with your next project?

Whether you're an architect, designer, engineer, builder or contractor, our technical experts offer free, tailored support and will come back to any enquiry within 48 hours. Let’s talk and we can help deploy your next project.

Continuing Professional Development (CPD) Seminar

At DuPont, we proudly collaborate with like RIBA (Royal Institute of British Architects) and CABE (Chartered Association of Building Engineers) to offer CPD seminars that enhance the skills of construction professionals and help navigate the complexities of Wall & Façade Design.

Enhance your expertise on vapour permeable and airtightness membranes in higher-risk buildings: gain valuable insights into functionality, fire safety regulations, and installation considerations.

Related Products

DuPont™ AirGuard® FR System Tape is a fire retardant, single-sided tape, with A2 Fire Class to EN 13501. Specially formulated for use with DuPont™ AirGuard® A2 FR AVCL for sealing all horizontal and vertical laps and around penetrations.

DuPont™ Tyvek® Double-sided Tape is ideal for sealing overlaps and bonding Tyvek® membranes together.

DuPont™ AirGuard® A2 FR AVCL enhances the building fabric in terms of airtightness, energy efficiency and moisture management, improving indoor air quality and providing exceptional fire safety to the building and its occupants.

Features & benefits

| Feature | Benefit |

|---|---|

| Performs to Euroclass A2 (s1, d0) standards |

|

| Highest level W1 class water-holdout |

|

| Superior breathability to 0.416 MNsg / SD 0.08m |

|

| All-in-one weatherproofing solution |

|

| Lighter weight product |

|

| Wider dimension of the roll reaching 1500 mm |

|

| 6 months of free exposure and UV resistance |

|

| Best-in-class 25-year warranty |

|

Physical properties

| Method | Unit | Value | |

|---|---|---|---|

| Reaction to fire | class | A2-s1,d0 (with Tyvek® 1310 FR Tape)* | |

| Water tightness | EN 1928 (A) | class | W1 |

| Water vapour transmission (Sd) | m | 0.08 | |

| Vapour Resistance | - | MN.s/g | 0.416 |

| UV Exposure | - | months | 6 |

| Mass per unit area | EN 1849-2 | g/m2 | 400 |

| Maximum tensile force (MD) | EN 12311-1 | N/50mm | 4000 |

| Elongation at max. tensile force (MD) | EN 12311-1 | % | 5 |

| Maximum tensile force (XD) | EN 12311-1 | N/50mm | 3500 |

| Elongation at max. tensile force (XD) | EN 12311-1 | % | 5 |

| Resistance to tearing MD (nail shank) | EN 12310-1 | N | 800 |

| Resistance to tearing XD (nail shank) | EN 12310-1 | N | 800 |

| Thickness | EN 1849-2 | mm | 3 |

*Installed on mineral board with EN 13501-1 fire class A1 and A2-s1,d0. DuPont™ AirGuard® FR system tape (1310FR) is used for sealing the overlaps which is included in the certificate. For further details, please request the classification report from BKC (tyvek.construction@dupont.com).