<p style="text-shadow: 2px 2px 5px rgba(0,0,0,1);">Warm Pitched Roof Construction</p>

Addressing WARM PITCHED ROOF risks with DuPont™ Tyvek® and AirGuard® system solution

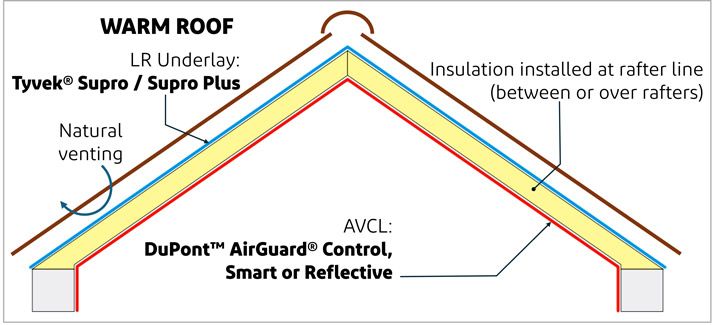

In warm pitched roofs, Tyvek® and AirGuard® membranes protect insulation and reduce humidity, thus improving energy efficiency. Insulation is placed at rafter level, creating a thermal envelope that minimizes heat loss and condensation risk.

Common types of insulation include rigid boards and breathable batt insulation, sometimes also ensuring a continuous layer above rafters, with detailed junctions and penetrations for performance. Requirements include well-fitted insulation meeting building regulations' R-values, an Air and Vapour Control Layer (AVCL) for humidity management and airtightness to prevent moisture build-up and condensation.

Addressing WARM PITCHED ROOF risks with Tyvek® Supro and Supro Plus

Tyvek® Supro and Supro Plus are breathable roofing underlays that allow moisture vapour to escape while blocking rain, managing condensation, and maintaining insulation. Tyvek® Supro Plus includes adhesive lap tape to enhance wind resistance and airtightness. Key features are Class W1 water resistance, high strength, and effective vapour permeability.

Benefits for stakeholders include:

- Architects and Designers: Confidently design with DuPont™ Tyvek® membranes for high-performance, durable structures that meet modern design and environmental standards, backed by DuPont's unwavering commitment to quality, service and innovation.

- Builders and Roofers: Superior weather resistance, easy installation, and extensive technical support (during and after installation), ensuring durable, high-performance roofing solutions that enhance efficiency and maintain professional reputation.

- Building Owners: The membranes deliver energy savings and maintain insulation effectiveness, reducing heating costs, safeguarding long-term roof integrity and avoiding potentially costly repairs or replacements.

Addressing WARM PITCHED ROOF risks with AirGuard® Products

The AirGuard® range enhances thermal performance and moisture control. AirGuard® Reflective reflects heat back, improving thermal efficiency and reducing heating costs, while AirGuard® Control prevents moisture ingress and maintains controlled moisture levels within the roof assembly. Benefits for stakeholders include:

- Architects and Designers: Optimal protection of the thermal insulation, significant reduction of interstitial condensation, and enhanced energy efficiency by eliminating the need for eaves and ridge ventilation, all while ensuring compliance with modern building regulations for architects' peace of mind.

- Builders and Roofers: Simplified and faster installation by removing the need for additional roof ventilation systems. Enhanced durability of roofing work by minimizing condensation risks and reducing potential wind damage, ultimately leading to safer and more energy-efficient roofs for the clients.

- Building Owners: AirGuard® products provide energy savings and protect structural integrity by managing moisture effectively, leading to lower heating bills and improved comfort.

Tyvek® Breather Membranes: Supro/Supro Plus

Tyvek® Supro is the market-leading breather membrane and is a water-resistant membrane suitable for all supported and unsupported pitched roof applications in commercial and residential buildings.

Tyvek® & AirGuard® Sealing Tapes

Tyvek® and AirGuard® sealing tapes and accessories are specifically designed to complement Tyvek® breather membranes and AirGuard® air and vapour control membranes. They help to seal the building envelope, offering optimal airtightness, energy efficiency, long-term performance and durability.

AirGuard®: Vapour Control Layer Solutions

An AirGuard® vapour control layer can significantly reduce heat loss and increase energy efficiency. By controlling heat transfer and reflecting heat inside the building, they help keep buildings cool in summer, and warm in winter.