<p style="text-shadow: 2px 2px 5px rgba(0,0,0,1);">Cold Pitched Roof Construction</p>

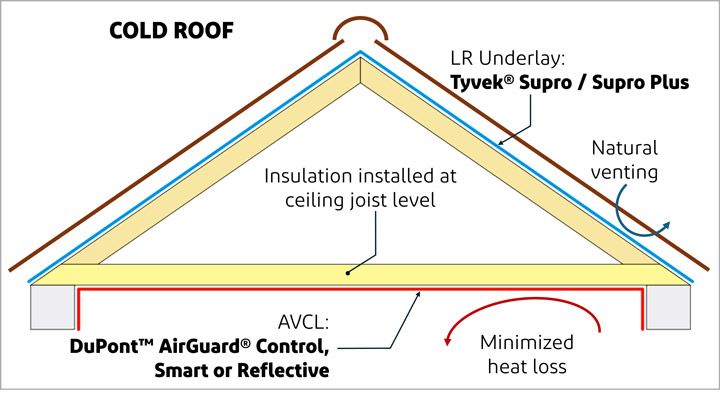

Addressing COLD PITCHED ROOF risks with DuPont™ Tyvek® and AirGuard® system solution

Tyvek® and AirGuard® membrane systems effectively manage condensation in cold pitched roofs by minimizing interstitial and surface condensation, ensuring optimal energy efficiency. These membranes allow water vapour to escape, reducing the need for ventilation openings that can compromise thermal efficiency.

To ensure airtightness at the ceiling level, separate the cold loft from the warm interior using AirGuard® Control, AirGuard® Reflective, or AirGuard® Smart, and tape all overlaps while sealing connections with our ancillaries. This prevents heated or conditioned air from escaping.

For weather protection below tiles, Tyvek® Supro and Supro Plus effectively drain wind-driven rain to the gutter. They are vapour-permeable and wind-tight when installed without ventilation gaps. Combined with ceiling-level airtightness and insulation, this solution creates a cost-effective cold roof. For enhanced performance, use Tyvek® Supro with taped laps.

Benefits for stakeholders include:

- Architects and Designers: possibility to address moisture issues to achieve the best possible energy label. DuPont™ Tyvek® Building Knowledge Centre with technical experts always available for assistance and project-based condensation risk analysis.

- Builders and Roofers: Compete effectively against other solutions in ventilated roofs and impress clients with lower heating bills.

- Building Owners: Enjoy lower heating and air conditioning costs with a dry loft that prevents rot, ensuring a comfortable indoor environment.

Tyvek® Breather Membranes: Supro/Supro Plus

Tyvek® Supro is the market-leading breather membrane and is a water-resistant membrane suitable for all supported and unsupported pitched roof applications in commercial and residential buildings.

Tyvek® & AirGuard® Sealing Tapes

Tyvek® and AirGuard® sealing tapes and accessories are specifically designed to complement Tyvek® breather membranes and AirGuard® air and vapour control membranes. They help to seal the building envelope, offering optimal airtightness, energy efficiency, long-term performance and durability.

AirGuard®: Vapour Control Layer Solutions

An AirGuard® vapour control layer can significantly reduce heat loss and increase energy efficiency. By controlling heat transfer and reflecting heat inside the building, they help keep buildings cool in summer, and warm in winter.