An Alternative to Multi-Layer Breathable Roofing Felt

Article

A Proven Alternative to Multi-Layer Breathable Roofing Felt

Roof underlays are often exposed to high temperatures – especially on buildings with a metal roof. Over time, this can significantly impair their water resistance – as can direct exposure to UV during construction. Since both factors can lead to a functionality loss of the second water shedding of the underlay leading to rot, mold, mildew, it is essential to choose a solution that has been proven to withstand both hazards effectively.

In a comprehensive ageing test commissioned by DuPont, Tyvek® breathable membranes outperformed multi-layer breathable roofing felts on both counts. The test programme, conducted by the SP Technical Research Institute of Sweden, found that DuPont™ Tyvek® breather membranes can still give effective watertight protection even after exposure to direct UV and sustained high temperatures.

UV Tests

During construction work, roofing underlays are often exposed to harmful UV for long periods, when roofs and walls are not covered quickly enough, or if completion is delayed. This exposure can dramatically reduce the watertightness of roofing felts.

Objective: To determine the watertight performance of Tyvek® breathable membranes after direct UV exposure.

All roof breather underlays have been subjected to direct UV, then tested to ensure their continued water resistance to class W1.

Results: Tyvek® demonstrated high durability and significantly superior resistance to UV exposure, without suffering damage.

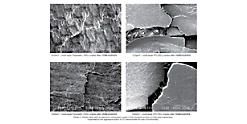

Microscopic pictures from microporous films of multi-layers breathable roofing felt after ageing

Tested underlays functional layers comparison

Heat Tests

Prolonged exposure to high temperatures can impair the watertightness of conventional multi-layer roofing underlays, leading to mold, mildew and other potential threats. Metal roofing is particularly prone to heat build-up, so particular care is required here when choosing the right solutions for long-term performance.

Objective: To determine the watertight performance of Tyvek® breathable membranes after heat exposure (90°C).

All roof breather underlays have been subjected to heat exposure of 90°C (above the CE requirement of 70°C) and then tested to ensure their continued water resistance to class W1.

Results: Again, Tyvek® demonstrated high durability and significantly superior resistance to temperatures of 90°C.

In Tyvek®, DuPont has created products that can withstand high levels of UV and heat exposure without losing their protective quality. This means choosing Tyvek® not only optimizes energy efficiency in all building types, but also gives proven durability and long-term protection.

High-Quality Functional Layer

The secret of Tyvek® breathable membranes lies in their unique structure. The highly durable functional layer is six to eight times thicker than most multi-layer roofing felts, and consists of heat- and UV stabilized polyethylene (PE) for reliable, long-term performance and UV/heat resistance – something competitor products cannot always guarantee.