TD148SWHTG

Tyvek® 400 Dual TG

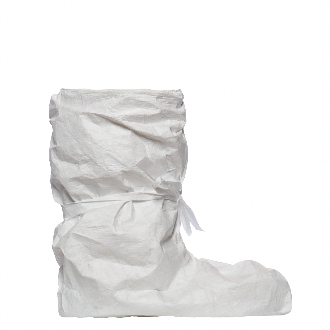

DuPont™ Tyvek® 400 Dual TD148S TG. Combined protection against fine particles and low-level sprays in a breathable, lightweight white hooded coverall with undergloves and socks, with Tyvek® at the front and a large breathable spunbond polypropylene back panel. Features stitched and taped seams on the upper body underarms and wrists where Tyvek® undergloves are attached for enhanced protection, a respirator fit two-piece hood, attached Tyvek® socks, an elasticated hood and waist (stitched-in), and a Tyvek® zipper with a pin lock slider zipper pull, a storm flap and a self-adhesive chin flap. Designed for environments where comfort matters while helping to provide protection from frontal exposure. Suitable for use in chemical mixing and handling, EV battery manufacturing, paint spraying, and tasks involving fine hazardous particles or composite materials.

DUPONT™ SAFESPEC™ Terms of Use

Product Selector Agreement

The following information must be read and accepted by the user before proceeding.

The DuPont™ SafeSPEC™ Product Selector Tools - Hazard, Industry, Guide, My Scenarios and Double-check- are intended to assist in choosing protective clothing for particular applications and does not replace the judgment of a qualified safety professional or industrial hygienist. Additional personal protective equipment, such as such as but not limited to: respiratory, eye, head, foot, and hand protection, may be required.

Supplying the proper hazard/chemical and exposure information for your hazard scenario is criticalin order to obtain an accurate recommendation. Inaccurate information could result in an improper recommendation. To ensure that the hazard/chemical information is accurate, consult the MSDS (Material Safety Data Sheet) supplied with the chemical. DuPont DISCLAIMS ANY RESPONSIBILITY OR LIABILITY FOR SUITS SELECTED USING these PRODUCT SELECTOR TOOLS, BASED ON ANY INCOMPLETE, INACCURATE, OR MISLEADING INFORMATION PROVIDED BY THE USER. There are other factors involved which could affect the final PPE (Personal Protective Equipment) decision and may not be considered in these Product Selector Tools. SafeSPEC™ Product Selector Tools provides information on DuPont suit styles for particular applications. The final decision on suit selection is the responsibility of the safety professional and end-user.

WARNING / CAUTION

There are uses, environments and chemicals for which any garment will be unsuitable. It is the responsibility of the user to review available data and verify that the garment selected is appropriate for the intended use and meets all specified government and industry standards.

Search by :

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

Step 1 of 3

You may enter from one to five chemicals or other hazards that may be present in your working environment. Our tool will find the best product match for the combined hazards. Enter a single chemical or hazard if you wish to find the best possible product match for that one hazard.

Chemical or Other Hazard Name

or

CAS Number

| Chemical Details | CAS | Actions |

|---|

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

Step 2 of 3

CHEMICAL COMPARISON

The table below shows the Normalized Breakthrough times of fabrics for the hazards selected. (Testing Details) You can find specific garments that protect against these hazards by clicking the 'Next' button below.

Done

Done

Done

|

|

|

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

Step 3 of 3

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

step3of3

Is Suitable For Hazard Scenario

Is Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

| Hazard | Fabric/Materials | Seam | Design |

|---|

Is Suitable For Hazard Scenario

Is Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

| Hazard | Fabric/Materials | Seam | Design |

|---|

| Name | Description |

|---|---|

| Full Part Number | TD148SWHTG |

| Fabric/Materials | Tyvek® 500 / SMS |

| Design | Hooded coverall with attached Tyvek® under gloves and attached Tyvek® socks, Tyvek® front, SMS back |

| Seam | Stitched seams which are also taped on the upper body: underarms and wrists |

| Color | White |

| Sizes | SM, MD, LG, XL, 2X, 3X |

| Quantity/Box | 25 per box, bulk packed. |

Related Products

DuPont™ Tychem® 2000 C Apron PA30L0. Durable yet lightweight frontal protection against a variety of industrial chemical threats in a yellow shin-length apron. Features neck and waist ties. Suitable for splash or pressurized splash protection in industrial environments such as pulp and paper, food processing, chemical processing, and pharmaceuticals.

DuPont™ Tychem® 2000 C Boot cover POBA. Durable yet lightweight partial body protection against a variety of industrial chemical threats in a yellow knee-length boot cover. Features ties and a slip-retardant sole. Suitable for splash or pressurized splash protection in industrial environments such as pulp and paper, food processing, chemical processing, and pharmaceuticals.

DuPont™ Tychem® 2000 C Sleeve PS32LA. Durable yet lightweight partial body protection against a variety of industrial chemical threats in a yellow sleeve. Features wide elastic cuffs and stiched and over-taped seams. Suitable for splash or pressurized splash protection in industrial environments such as pulp and paper, food processing, chemical processing, and pharmaceuticals.

DuPont™ Tychem® 2000 C Gown 0290. Durable yet lightweight partial body protection against a variety of industrial chemical threats in a yellow shin-length gown. Features a wrap-over rear closure, a mandarin collar, double cuffs, and waist ties. Suitable for splash or pressurized splash protection in industrial environments such as pulp and paper, food processing, chemical processing, and pharmaceuticals.

DuPont™ Tyvek® 500 Boot cover with antislip POBA. Designed for use with Tyvek® apparel, Tyvek® accessories can provide enhanced protection for exposed body parts against hazardous substances. This white boot cover features stitched internal seams, a slip-retardant sole, an elastic top, and fixation ties. Suitable for a variety of applications including pharmaceutical handling, chemical protection, general maintenance/operations, spray painting, and general clean-up.

FEATURES & PRODUCT DETAILS

DuPont™ Tyvek® 400 Dual TG. Hooded coverall combining Tyvek® at the front with a SMS nonwoven on the back panel. Available in sizes SM to 3X. Attached Tyvek® under gloves. Attached Tyvek® socks. 2-piece hood and gusset for optimal fit. Elasticated hood and waist. White.Tyvek® front provides an ideal balance of protection, durability and comfort. It is permeable to both air and water vapor, yet repels water-based liquids and aerosols. It offers an excellent barrier against fine particles and fibres down to 1 micron in size on the Tyvek® front. It is ultra-low-linting and antistatically treated. Silicone non-added. The large, breathable back panel, made of SMS nonwoven, offers lower protection against particles and light water-based splashes, yet high levels of comfort.Tyvek® 400 Dual TG is designed for specific applications that demand comfort while helping to provide protection from frontal exposure during applications such as mixing/handling of chemicals* in chemical industry and for EV battery manufacturing in particular, as well as paint spraying and tasks involving fine hazardous particles or composite materials.Thanks to the taped underarm seams on the upper body, it offers increased protection also for the chemicals/products/process against potential contamination from the wearer or from garment seams during the typical work activity.*The user must ensure suitable reagent to garment compatibility before use. Please refer to chemical permeation data available in SafeSPEC™ to determine the level of protection needed.

- Certified according to Regulation (EU) 2016/425.

- Chemical protective clothing, Category III, Type 5 and 6.

- Antistatic treatment (EN 1149-5) - on both sides.

- Adapted wrist protection with the attached Tyvek® under gloves

- Enhanced protection of ankles and feet with the attached Tyvek® socks

- Modified hood for a better fit with respiratory helmets

- Stitched seams which are also taped on the upper body underarms and wrists for enhanced protection both for the wearer and the process

- Tyvek® zipper and zipper flap for enhanced protection

- Throat protection thanks to chin flap with adhesive tape

- Superior barrier properties for enhanced particle and liquid protection along with high comfort due to its breathable back panel.