TY198S HP

Tyvek® 500 HP

DuPont™ Tyvek® 500 HP TY198S HP. Robust yet lightweight protection against hazardous particles and low-level sprays in a white hooded coverall with a back pass-thru system. Designed specifically to be worn over full-body harnesses, protecting the wearer, the harness and the rope lanyard when attached to the back D-Ring. Features stitched internal seams, a respirator fit two-piece hood, a hook and loop closure for secure connection to the carabiner, an integrated back pass-thru system designed to cover the rope lanyard, snap closures for a tight seal when the pass-thru is not in use, elasticated wrists, ankles, face, and waist (glued-in), a Tyvek® zipper with a pin lock slider zipper pull, a storm flap, and a self-adhesive chin flap. Suitable for a variety of working-at-height applications including painting, maintenance, asbestos removal, and cleaning.

DUPONT™ SAFESPEC™ Terms of Use

Product Selector Agreement

The following information must be read and accepted by the user before proceeding.

The DuPont™ SafeSPEC™ Product Selector Tools - Hazard, Industry, Guide, My Scenarios and Double-check- are intended to assist in choosing protective clothing for particular applications and does not replace the judgment of a qualified safety professional or industrial hygienist. Additional personal protective equipment, such as such as but not limited to: respiratory, eye, head, foot, and hand protection, may be required.

Supplying the proper hazard/chemical and exposure information for your hazard scenario is criticalin order to obtain an accurate recommendation. Inaccurate information could result in an improper recommendation. To ensure that the hazard/chemical information is accurate, consult the MSDS (Material Safety Data Sheet) supplied with the chemical. DuPont DISCLAIMS ANY RESPONSIBILITY OR LIABILITY FOR SUITS SELECTED USING these PRODUCT SELECTOR TOOLS, BASED ON ANY INCOMPLETE, INACCURATE, OR MISLEADING INFORMATION PROVIDED BY THE USER. There are other factors involved which could affect the final PPE (Personal Protective Equipment) decision and may not be considered in these Product Selector Tools. SafeSPEC™ Product Selector Tools provides information on DuPont suit styles for particular applications. The final decision on suit selection is the responsibility of the safety professional and end-user.

WARNING / CAUTION

There are uses, environments and chemicals for which any garment will be unsuitable. It is the responsibility of the user to review available data and verify that the garment selected is appropriate for the intended use and meets all specified government and industry standards.

Search by :

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

Step 1 of 3

You may enter from one to five chemicals or other hazards that may be present in your working environment. Our tool will find the best product match for the combined hazards. Enter a single chemical or hazard if you wish to find the best possible product match for that one hazard.

Chemical or Other Hazard Name

or

CAS Number

| Chemical Details | CAS | Actions |

|---|

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

Step 2 of 3

CHEMICAL COMPARISON

The table below shows the Normalized Breakthrough times of fabrics for the hazards selected. (Testing Details) You can find specific garments that protect against these hazards by clicking the 'Next' button below.

Done

Done

Done

|

|

|

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

Step 3 of 3

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

step3of3

Is Suitable For Hazard Scenario

Is Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

| Hazard | Fabric/Materials | Seam | Design |

|---|

Is Suitable For Hazard Scenario

Is Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

| Hazard | Fabric/Materials | Seam | Design |

|---|

| Name | Description |

|---|---|

| Full Part Number | model TY198S HP |

| Fabric/Materials | Tyvek® 500 |

| Design | Hooded coverall with thumb loops and back pass-thru system with snap closure |

| Seam | Stitched (internal) |

| Color | White |

| Sizes | SM, MD, LG, XL, 2X, 3X |

| Quantity/Box | 25 per box |

Related Products

DuPont™ Tyvek® 500 Shoe cover with antislip POSA. Designed for use with Tyvek® apparel, Tyvek® accessories can provide enhanced protection for exposed body parts against hazardous substances. This white shoe cover features stitched internal seams, a slip-retardant sole, and an elasticated ankle. Suitable for a variety of applications including pharmaceutical handling, chemical protection, general maintenance/operations, spray painting, and general clean-up.

DuPont™ Tyvek® 500 Shoe cover POS0. Designed for use with Tyvek® apparel, Tyvek® accessories can provide enhanced protection for exposed body parts against hazardous substances. This white shoe cover features stitched internal seams and an elasticated ankle. Suitable for a variety of applications including pharmaceutical handling, chemical protection, general maintenance/operations, spray painting, and general clean-up.

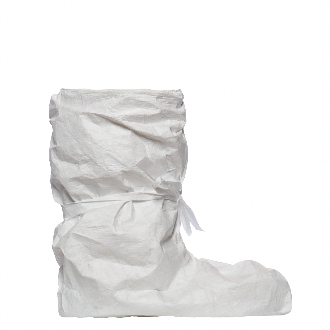

DuPont™ Tyvek® 500 Boot cover POB0. Designed for use with Tyvek® apparel, Tyvek® accessories can provide enhanced protection for exposed body parts against hazardous substances. This white boot cover features stitched internal seams, an elastic top, and fixation ties. Suitable for a variety of applications including pharmaceutical handling, chemical protection, general maintenance/operations, spray painting, and general clean-up.

DuPont™ Tyvek® 500 Boot cover with antislip POBA. Designed for use with Tyvek® apparel, Tyvek® accessories can provide enhanced protection for exposed body parts against hazardous substances. This white boot cover features stitched internal seams, a slip-retardant sole, an elastic top, and fixation ties. Suitable for a variety of applications including pharmaceutical handling, chemical protection, general maintenance/operations, spray painting, and general clean-up.

DuPont™ Tyvek® 500 Xpert CHF5/ Tyvek® 500 Xpert CHF5 Eco Pack. Robust yet lightweight protection providing an excellent barrier against fine particles and low-level sprays in a white hooded coverall. Features stitched external seams, a respirator fit three-piece hood, an ergonomic design, elasticated wrists, ankles, face, and waist (glued-in), and a Tyvek® zipper with a pin lock slider zipper pull and a storm flap. Also available in Eco Pack, a significantly reduced packaging format compared to standard packaging. Suitable for a variety of applications including pharmaceutical handling, chemical processing, general maintenance, and spray painting.

DuPont™ Tyvek® 600 Plus CHA5. Robust yet lightweight protection providing an excellent barrier against fine particles and high level sprays in a hooded coverall. Features stitched and over-taped seams, a respirator fit two-piece hood, thumb loops, tunnelled elastication at wrists, ankles, and face, elasticated waist (glued-in), a Tyvek® zipper with a pin lock slider zipper pull and with a self-adhesive storm flap, and a chin flap. Suitable for a variety of applications including maintenance and dismantling in the nuclear industry, lead and asbestos abatement/remediation, pharmaceutical manufacturing, research laboratories and exposure to biological hazards.

FEATURES & PRODUCT DETAILS

Avoid the need to compromise between fall or chemical protection.

Workers operating at height and requiring chemical protection at the same time previously had to compromise between personal protection from chemical threats and the fall protection system. The harness would be worn over the top of a coverall, exposing it to potential chemical contamination and leading to costly replacement of equipment, or wearing the harness inside a coverall and cutting a hole to attach the rope lanyard, leaving the user exposed to contamination.

The Tyvek® 500 HP offers the wearer full protection by housing the rope lanyard within a sealed compartment giving access to the harness worn underneath, helping to maintain an effective barrier between the user and equipment and any chemical threat.

Protect your fall arrest equipment / lanyard worn underneath & the worker thanks to the back pass-thru system and the hook and loop closure at the end. Internal stitched seams for increased protection of the processes. Protection of the wearer thanks to the tight design through sealable chin flap & zipper flaps, thumb loops, snap closure system for the pass-thru. Superior chemical protection and durability thanks to the unique Tyvek® fabric. Extremely lightweight offering high level of comfort and mobility. Free of silicone, oil, grease, contaminates, foreign materials, and surface irregularities (suitable for paint applications), maintenance at height - asbestos removal, cleaning

- EN 14126 (barrier to infective agents), EN 1073-2 (protection against radioactive contamination)..

- Antistatic treatment (EN 1149-5) - on both sides.

- Stitched internal seams

- Hook and loop closure when connecting to the carabiner

- Pass-thru system to protect the lanyard

- Snap closure for full tightness when pass-thru is not used

- 2-piece hooded coverall for good fit around respirator

- Sealable chin flap & zipper flaps

- Elasticated cuffs with thumb loops

- Elasticated ankles

- Ample crotch area

- Overall ergonomic pattern

- Data available from "Fall test" (mannequin drop test)

- Thanks to the conical shape of the rope cover, there is enough fabric at the back which enables limited pulling effect from the rest of the garment (ie. neck area) in the event of a fall and presents an additional advantage when using fall arrest systems with shock absorbers

Fabric & Permeation/Penetration Data

Physical Properties

Data relating to mechanical performance of the fabrics used in DuPont chemical protective clothing, listed for the selected garment according to the test methods and relevant European standard, if applicable. Such properties, including abrasion and flex-cracking resistance, tensile strength and puncture resistance can help in the assessment of protective performance.

| Property | Test Method | Typical Result | EN |

|---|---|---|---|

| Abrasion Resistance 7 | EN 530 Method 2 | >100 cycles | 2/6 1 |

| Basis Weight | DIN EN ISO 536 | 41.5 g/m2 | N/A |

| Colour | N/A. | White | N/A |

| Exposure to high Temperature | N/A. | Melting point ~135 °C | N/A |

| Flex Cracking Resistance 7 | EN ISO 7854 Method B | >100000 cycles | 6/6 1 |

| Puncture Resistance | EN 863 | >10 N | 2/6 1 |

| Resistance to water penetration | AATCC 127 | >10 kPa | N/A |

| Surface Resistance at RH 25%, inside 7 | EN 1149-1 | < 2,5 • 109 Ohm | N/A |

| Surface Resistance at RH 25%, outside 7 | EN 1149-1 | < 2,5 • 109 Ohm | N/A |

| Tensile Strength (MD) | DIN EN ISO 13934-1 | >60 N | 2/6 1 |

| Tensile Strength (XD) | DIN EN ISO 13934-1 | >60 N | 2/6 1 |

| Trapezoidal Tear Resistance (MD) | EN ISO 9073-4 | >10 N | 1/6 1 |

| Trapezoidal Tear Resistance (XD) | EN ISO 9073-4 | >10 N | 1/6 1 |

- According to EN 14325

- According to EN 14126

- According to EN 1073-2

- According to EN ISO 14116

- According to EN ISO 11612

- Front Tyvek ® / Back

- Based on test according to ASTM D-572

- See Instructions for Use for further information, limitations and warnings

- Larger than

- Smaller than

- Smaller than or equal to

- Not Applicable

- Standard Deviation