Automotive

Global and regional customers count on us to deliver game-changing ideas and materials solutions.

We collaborate with customers and suppliers across every vehicle sector. With support from hundreds of DuPont engineers, researchers, and scientists, we help customers achieve results in:

• Electrification and advanced mobility

• Safety, durability, and lightweighting

• Advanced engineering

• Part design, consolidation, and testing

• Improved efficiencies

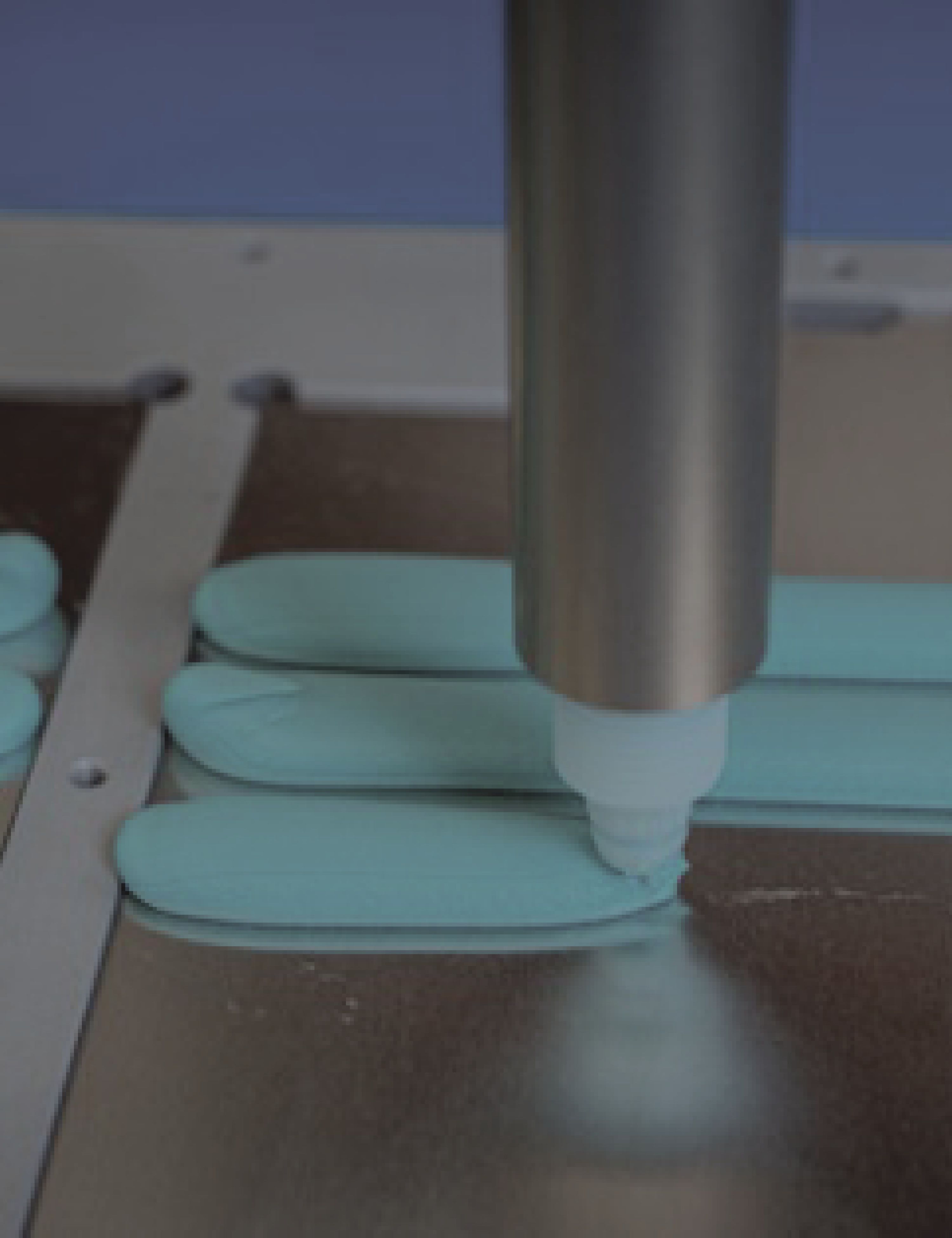

Innovative materials solutions

Our products are backed by people who have extensive expertise in application development, testing, and quality.

Solutions that ensure the safe and efficient operation of brake systems for drivers around the world.

We can help you advance automotive design and manufacturing

Teams at our global Centers of Excellence for Automotive Electrification have the expertise that can identify and create solutions for even your most difficult challenges.

)