VESPEL® ASB ASSEMBLIES

DuPont™ Vespel® ASB Assemblies

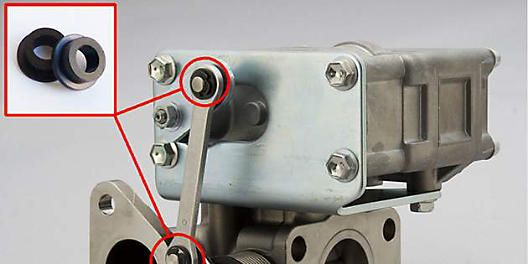

Vespel® ASB assemblies include fastening/bonding composites or carbon-graphites to supporting metallic structures or overmolding/insert molding one material with another material, such as a thermoplastic.

Such integration capabilities provide an expanded set of possibilities to help solve challenges.

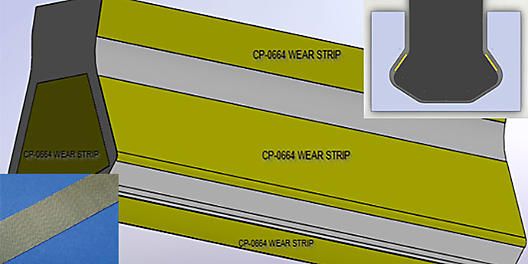

ASB-0664, ASB-0670

Track liners and wear strips comprised of composite liners bonded to metal retainers for high load applications

ASB-0826 & ASB-3000

Higher thermal capability than ASB-0664 and ASB 0670. Intended for self-lubricating bushings that require high load capacity.

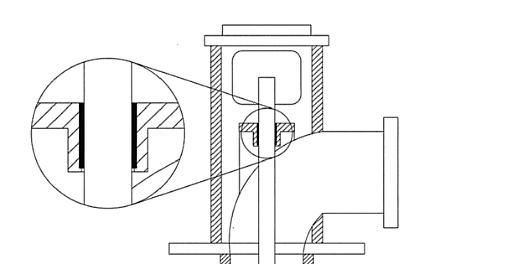

ASB-5000 SERIES

Carbon-graphite, metal-backed assemblies used in applications where polymeric composites are not suitable due to thermal limitations. The metal backing provides ease of assembly while the carbon-graphite liners provide the self-lubrication and low wear at temperatures up to 675°C (1250°F) in oxidative environments.

USES AND APPLICATIONS

DuPont™ Vespel® parts have a unique combination of properties that can replace metal, PEEK or ceramic parts in material handling equipment with high temperatures, high wear or no lubrication.

CASE STUDIES

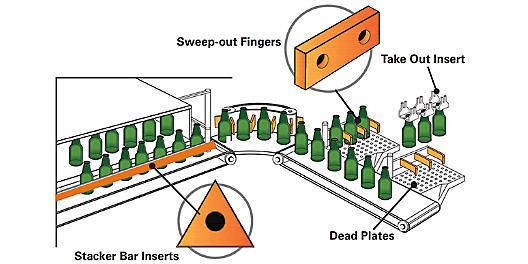

Vespel® SCP-5050 sweep-out fingers and stacker bar inserts for glass handling help increase plant reliability and efficiency and reduce operating costs at Veda-Pack glass manufacturing sites

The operator of a pipeline in the Southwestern U.S. was searching for a case ring material for pumps that would enable improved operating efficiency, increase equipment reliability and avoid the seizing or galling problems encountered with metal components. The metal components were replaced with Vespel® CR-6100 parts, and the results were impressive.

INFORMATION & IDEAS

Low friction plastic applications developed in collaboration with DuPont experts can help improve durability and performance, reduce maintenance, and can even contribute to reduced use of fossil fuels.

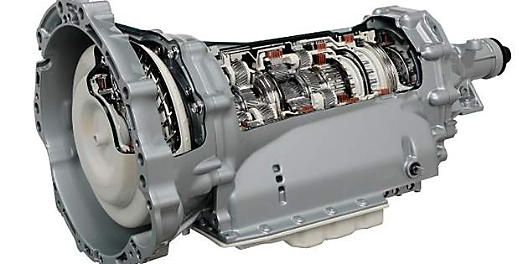

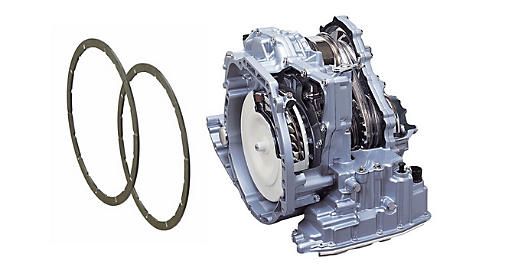

DuPont™ Vespel® parts and shapes and DuPont™ Delrin® acetal resin are high-strength, low-friction mechanical plastics that deliver performance for automotive, consumer, and industrial applications.

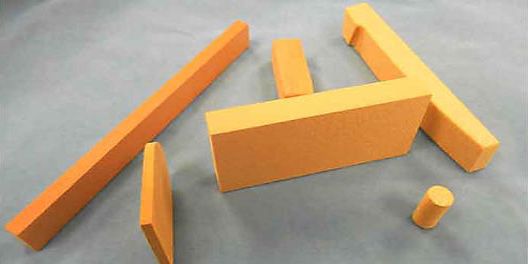

Vespel® products are made from a variety of materials (polyimides, thermoplastics, composites and chemically-resistant polymers). These products offer a unique combination of physical properties and design flexibility. Parts are available as custom parts, stock shapes, components or assemblies.

DuPont™ Vespel® parts offer low friction, lightweight and durable metal replacement in automotive transmission applications.